Pressure Rating

Determining the pressure rating of the new vessel is generally the first major parameter to determine. The pressure rating should be at least 10% higher than the expected maximum operating pressure at the operating temperature. This will avoid stress on the relief device that is required for all pressure vessels and will avoid a release of chemicals for small pressure excursions above the normal operating pressure.

If the pressure rating is higher than ~50 psig (~3.5 bar), consideration should be given to rating the vessel for full vacuum even if the current application does not require it. Vessels rated for this pressure and higher can generally be rated for full vacuum without an increase in vessel wall thickness and cost.

Temperature Rating

The maximum and minimum temperature rating of the vessel has a significant impact on the vessel wall thickness and type of steel used. The maximum temperature rating should be 50 to 100 °F (30 to 50°C) higher than the expected maximum operating temperature to allow for any upset conditions. The minimum temperature rating should be the lowest expected minimum including outdoor ambient conditions if the vessel is located outside.

Material of construction

Selection of the construction material depends on the potential corrosivity of the process, the expected minimum and maximum temperatures, and cost. Vessels made of carbon steel are the least expensive. If the process is only marginally corrosive to carbon steel, including a corrosion allowance may allow for a long vessel life and still be the least expensive option.

Stainless steel vessels are more expensive but offer corrosion resistance to most chemicals and can be used for temperatures down to -325 °F (-200 °C).

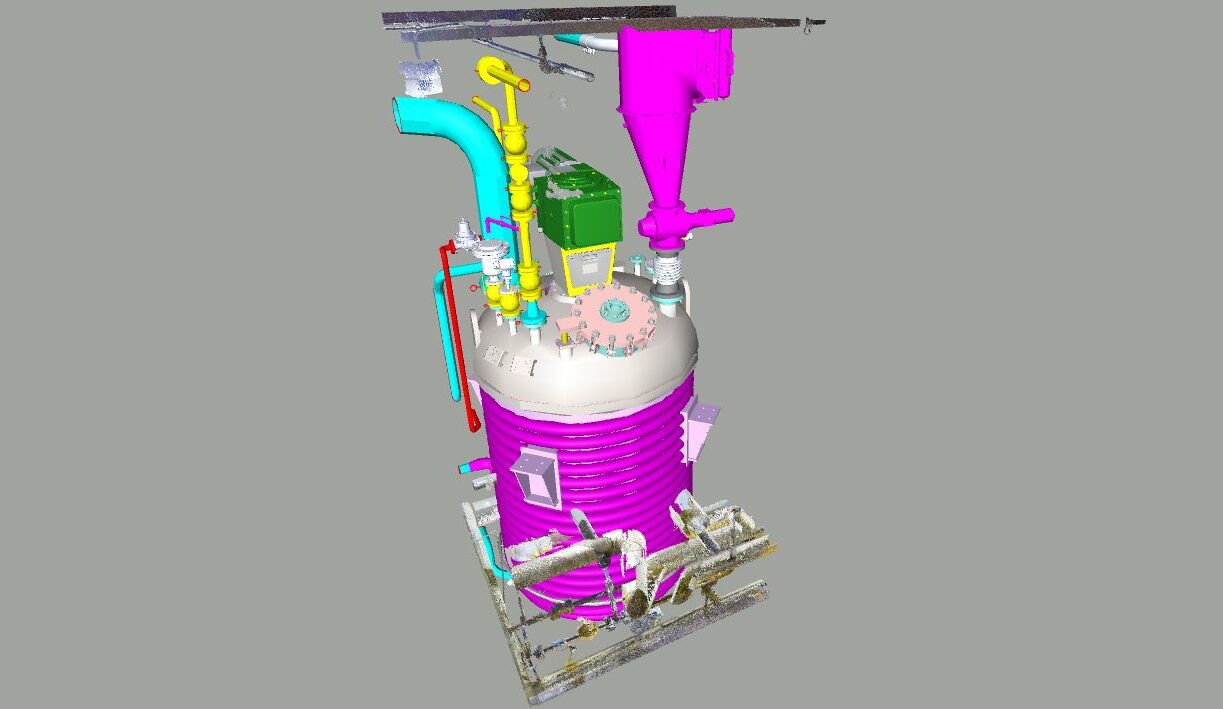

Size and Configuration

The following items will help determine the physical size and configuration of the vessel:

- Volume required for the process

- Space limitations

- How to support the vessel

- Configuration required for the process; i.e tall/skinny vs short/wide; horizontal/vertical

- Heating and/or cooling jacket requirements

- Possible vessel Internal components (e.g., dip pipe, baffles, agitator support)

- Insulation needs

Future blogs will include more details on pressure vessel design and will discuss other vessel related topics such as heat exchangers, atmospheric storage tanks, and relief devices.