Front-End Engineering and Design (FEED) studies minimize project uncertainty, leading to tangible cost benefits as a result of better controlled project costs. Below, we explore a real-world example to highlight the positive impact up-front planning has on project costs.

Diminish Uncertainty through FEED Studies

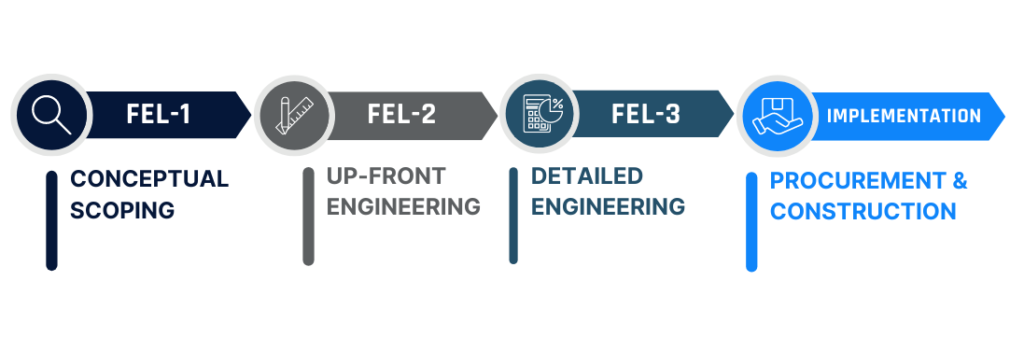

FEED studies are a strategic investment in reducing project uncertainty. By allocating as little as 2-3% of overall project costs towards an FEL-2 study focused on feasibility and preliminary engineering, uncertainty can be diminished by at least 20%.

It is important to recognize how unchecked uncertainty compounds in various forms, including inflated general contractor markups, risk premiums such as safety factors, installation costs, and profit margins. Note that a nearly complete overlap exists between work done in a FEED study and the detailed engineering and design required for all projects, so additional investment for the FEED study is minimal. The distinction lies not in whether these steps are taken, but in what order they are completed to influence and reduce potential cost overruns.

By extending the initial investment to around 5-7% of overall project funding to complete the detailed engineering and design effort (FEL-3), the risk of potential overrun on the overall project budget typically remains confined to no more than 10-15%. This strategic front-loading of the design process serves as a guard against unforeseen expenses and ensures a smoother project trajectory.

Example: A $10 Million Dollar Project, Based on Real-World Project Costs

In an ideal world, a meticulously planned and executed project would adhere closely to its budget. Consider a project that should cost around $10M. Each project comes with a unique set of challenges that can lead to cost overruns, such as unforeseen gaps, change orders, compliance issues, and the temptation to short circuit the FEED study, leading to post-installation rework.

It is important to recognize that opting for the convenience of a single point of contact, typically a general contractor, often includes a markup of around 10% on everything downstream due to the risk premium they incorporate. While that markup may be acceptable and reasonable on many projects, be mindful of any remaining uncertainty at the point of engaging a general or mechanical contractor. Any uncertainty passed along to these groups, and often preventable through the correct use of a FEED study, can have a significant compounding effect when paired with markups and risk premiums.

Given these considerations, the value of an up-front FEED study becomes apparent. Ideally, opt for a partnership with firms that offer ‘open book pricing.’ This approach provides transparency, reducing the uncertainties typically padded into lump sum pricing. Industry studies have consistently shown that projects managed with this level of upfront planning and transparency meet budget expectations more reliably compared to those relying on traditional lump sum pricing models. Committing to the FEED study as the first step can safeguard against the inflation of project costs and ensure a more predictable financial outcome.

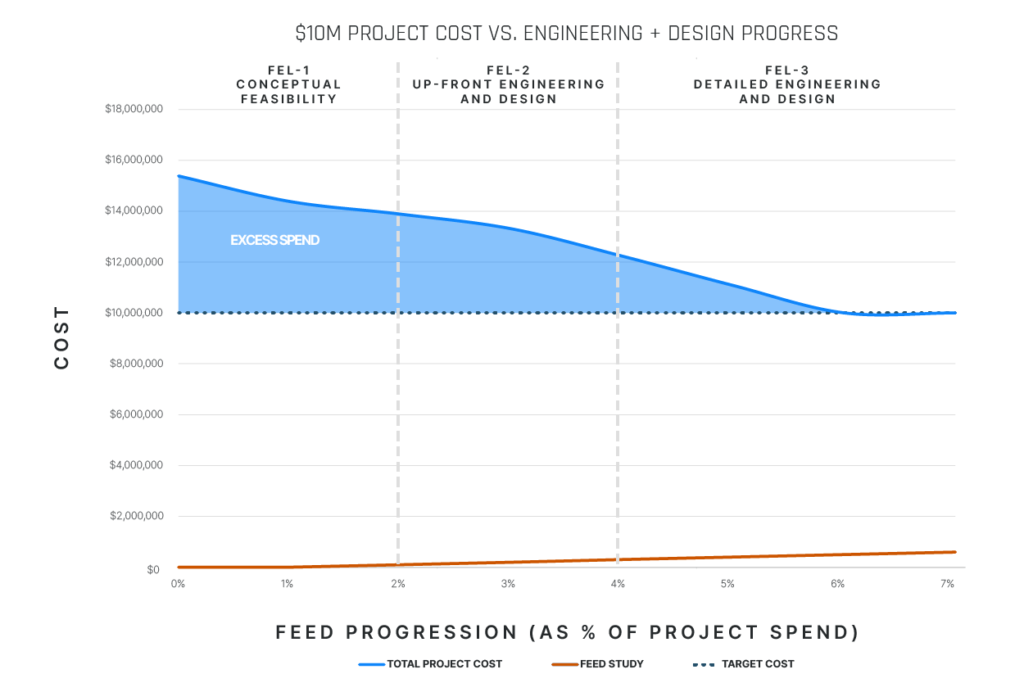

We took several recent projects that employed FEED studies to varying degrees and normalized all projects to a $10 million spend. The image below shows the results, charting out overall project costs and potential overages relative to the FEED stage.

Without a FEED study, the overall project costs for the project $10M project are at $15.4M. When a FEED study employs just 2% of project budget, the overall project spend is reduced 9.7% to $13.9M. When 7% of spend is employed for the FEED study, project costs come in at $10M, a 35% reduction in overall cost when compared to the version with no FEED study.

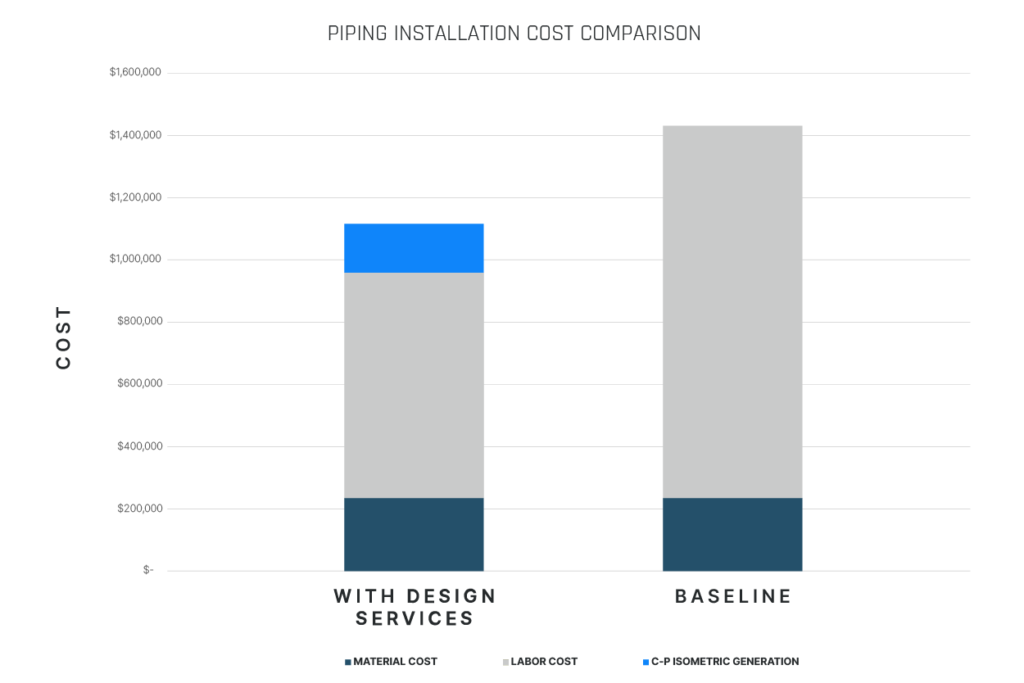

Real-World Impact of Piping Isometrics on Cost Reduction

Let’s zoom in on one specific aspect of a project: piping design, and generating a detailed isometric with a complete bill of materials. A recent client originally declined generating piping isometrics at the project start, a decision that threatened to surge on-site labor costs and change orders dramatically. Fortunately, the mechanical contractor engaged C-P Systems for isometric generation, which facilitated a shift to mostly off-site fabrication.

This led to a 70% savings on the more costly on-site labor and only a 30% increase in the lower cost off-site labor. Considering the dramatic cost difference between on-site and off-site piping fabrication, this led to an overall piping installation cost savings of 22% with piping isometrics, compared to total cost without piping isometrics.

Beyond the Numbers

Reducing uncertainty through diligent, up-front engineering studies is not merely a best practice—it’s a cost-saving imperative. Our recent project stands as testament to the tangible benefits of this approach, where thorough, early planning and strategic decision-making lead to significant financial savings and project success. Interested in learning how C-P Systems can help reduce your project costs through FEED studies and piping isometrics? Contact us for a consult today.