Beyond Compliance: Where Piping Engineering Meets Experience

Meeting regulatory requirements is essential. But it’s only the starting point. The art of piping design begins where the specifications end: deciding how to route a pipe when space is tight, how to avoid a future maintenance nightmare, or how to bring order to a tangle of systems. These aren’t answers you find in a manual. They come from knowing how plants are built, operated, and maintained, and from having seen what happens when you get it wrong.

Great designs “make sense” at first glance. The flow paths and system relationships are immediately, intuitively apparent. Equipment arrangements follow operational logic, not just spatial efficiency. The design tells the story of the process clearly, allowing operators and engineers to focus on what really matters: the process itself. Without this clarity, operators have to mentally decode complex visual puzzles to understand system relationships.

Field-First Thinking, Visually Communicated

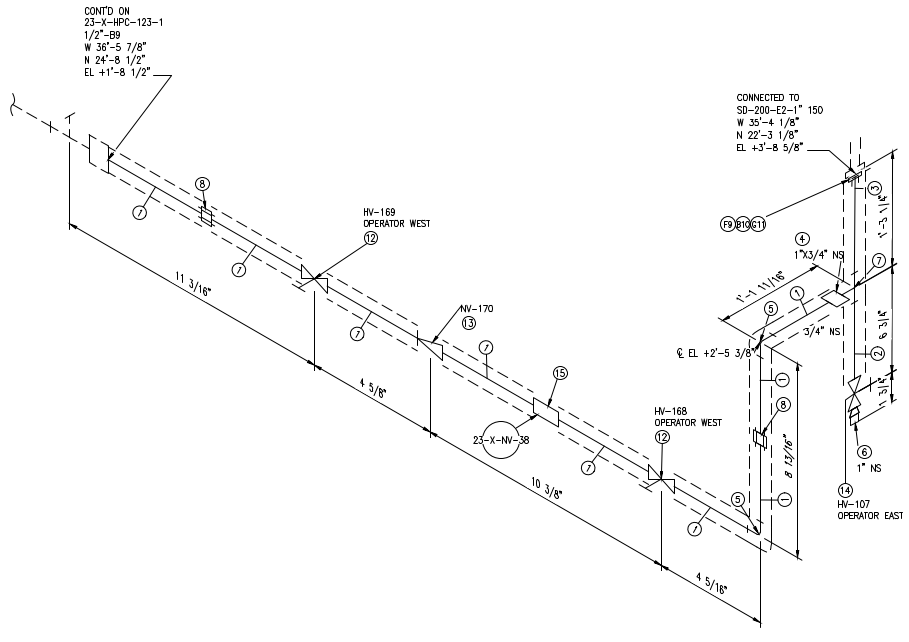

Good piping design isn’t just technically accurate; it’s visually intuitive. Designers think in three dimensions, anticipating how a welder will run a bead, how a valve will be accessed, or how a line will drain. They sketch ideas that feel balanced. They space components to reduce clutter and simplify tracing. They avoid traps like high points that can’t vent or low points that can’t drain.

These instincts are built from thousands of hours thinking through real-world consequences. When experienced designers can “read” a 3D space and understand how it will feel to work in that environment, they create designs that accommodate reasonable changes without major rework. They think ahead.

What Makes Piping Design “Look Right”?

Experienced designers can look at a layout and know instantly if something feels off, even before clash detection or modeling is complete. There’s a certain elegance to designs that:

- Minimize congestion while maintaining accessibility

- Avoid awkward offsets and clearly show intent

- Find ways to make complex systems appear simple

- Incorporate visual hierarchy (the tank should be larger than the pump)

- Use intentional white space rather than cramming everything into minimum footprint

When everything just fits, when lines flow cleanly, when access and spacing feel natural, when the complex appears simple, it’s not just beautiful, it’s buildable. Great designs eliminate unnecessary complexity while addressing all functional requirements. They incorporate visual hierarchy so critical components stand out appropriately.

The Wisdom of Experience

Field experience plays a critical role in developing design instincts that go beyond what software or standards can prescribe. When designers have seen what works and what doesn’t work in the field, they translate that experience into designs that utilize space optimally while avoiding common operational pitfalls.

This experience teaches designers to anticipate practical problems: space constraints, installation sequences, and maintenance access. It also sharpens their ability to visualize how an installation will come together step by step. It’s the difference between designing systems that are technically compliant but practically impossible to construct, and creating arrangements where components work together harmoniously during installation, operation, and maintenance.

The Art of 2D Piping Design: Where Clarity Meets Reality

While 3D models capture spatial relationships, the art of piping design extends powerfully into 2D documentation, particularly P&IDs, where visual communication becomes critical for operations and maintenance teams.

Great 2D design goes far beyond technical accuracy. It’s about creating drawings that tell the story of the process clearly, minimizing confusion between documented systems and field reality. Here’s how the visual design choices made in 2D P&IDs impact the people who rely on them every day:

|

2D Design Element |

Artistic Approach |

Impact on Users |

|

Equipment Placement |

Mirrors actual spatial relationships (pump below tank) |

Operators understand system relationships without mental translation |

|

Component Representation |

Shows operational reality (removable dip tube includes flange) |

Maintenance teams see what they’ll actually encounter in the field |

|

Flow Meter Details |

Depicted as installed (flanged, tapped, differential pressure) |

Specifications match field installation requirements |

|

Line Routing |

Minimizes crisscrossing, follows logical flow paths |

Keeps drawings readable and traceable |

|

Information Hierarchy |

Critical details stand out, supporting info accessible but uncluttered |

Users focus on what matters most for their specific task |

|

Sheet Organization |

Balances completeness against excessive off-page connectors |

Process understanding flows naturally without constant page-flipping |

The goal is drawings that serve as effective communication tools rather than just technically compliant documentation. When 2D designs successfully bridge the gap between engineering intent and field reality, they become invaluable references that support safe, efficient operations throughout the system’s lifecycle.

The Hand Sketch Lives On

Even in a world of point clouds and 3D models, the hand sketch remains one of the designer’s most powerful tools. A quick redline, an annotated scan, a sketched-up concept; these visuals bridge the gap between software and understanding. They show not just what to build, but why it was built that way.

Hand sketches communicate so effectively because they focus on intent rather than perfection. They can capture spatial relationships, construction sequences, and design rationale in ways that formal drawings sometimes cannot. The best designs often integrate stakeholder input early in the process, when changes can still influence outcomes without impacting schedules. This collaborative approach, combined with cross-disciplinary coordination and field-validated decisions, ensures that artistic vision translates into practical results.

When Technology Serves Piping Design (Not the Other Way Around)

One hallmark of experienced design is knowing where to focus effort for maximum impact. Modern software offers impressive capabilities, like embedding detailed technical specifications, instrument data sheets, and maintenance procedures directly into 3D models. While this sounds revolutionary, the reality is more complex.

The fundamental question becomes: who actually needs this information, and how do they access it?

In practice, the teams who need detailed specs such as maintenance, operations, and procurement rarely use 3D modeling tools. Meanwhile, keeping embedded data up to date can add more overhead than value.

For most teams, centralized document control systems are still the most practical solution. They’re accessible, searchable, and usable by anyone. No modeling software required. The model should focus on what it does best: spatial relationships, constructability, and clash detection.

This doesn’t mean rejecting new technology. It means understanding what adds real value versus what creates impressive demonstrations. Experienced designers guide clients toward solutions that improve actual project outcomes rather than pursuing software capabilities that look sophisticated but don’t translate to better construction, operation, or maintenance.

Where Art Meets Piping Engineering

The art of piping design bridges technical requirements and practical reality. It’s what separates systems that merely function from systems that function beautifully efficiently, safely, and sustainably for decades.

This artistry shows up in the details: how components are grouped for operational logic, how white space is used intentionally rather than cramped layouts, how valve arrangements follow maintenance workflows rather than just spatial constraints. It appears in designs that eliminate unnecessary complexity while addressing all functional requirements.

Well-executed piping design considers everything fluid properties, system configuration, plant realities, applicable standards, and the human factor. How will real people interact with this system during construction, startup, operation, maintenance, and eventual modification?

The return on this approach is measurable. Thoughtful design increases process uptime, minimizes safety incidents, reduces maintenance labor, and creates room for future expansion. It transforms initial capital investment into long-term operational advantage.

The art of piping design isn’t automatic or guaranteed. It takes deliberate choices, field awareness, and a deep understanding of how systems are built, used, and maintained. It’s what transforms technical drawings and isometrics into systems that operate reliably for years, not just on paper but in the real world.

Exceptional piping design demands both technical expertise and hard-won field wisdom. When you need systems that perform as beautifully as they function, experience is essential.