The road to an efficient and successful project requires a good understanding of what is needed for the process, and to have that clearly identified and defined at the beginning. Asking the correct questions to define the bounds of scope are crucial for avoiding one of the greatest inefficiencies, rework. The scope of work is not just dictated by the process, and other disciplines must be engaged to help set these boundaries. Here are a few things to accomplish at the beginning of the project to be sure your initial work avoids some of the most common pitfalls.

Proper Scope Definition

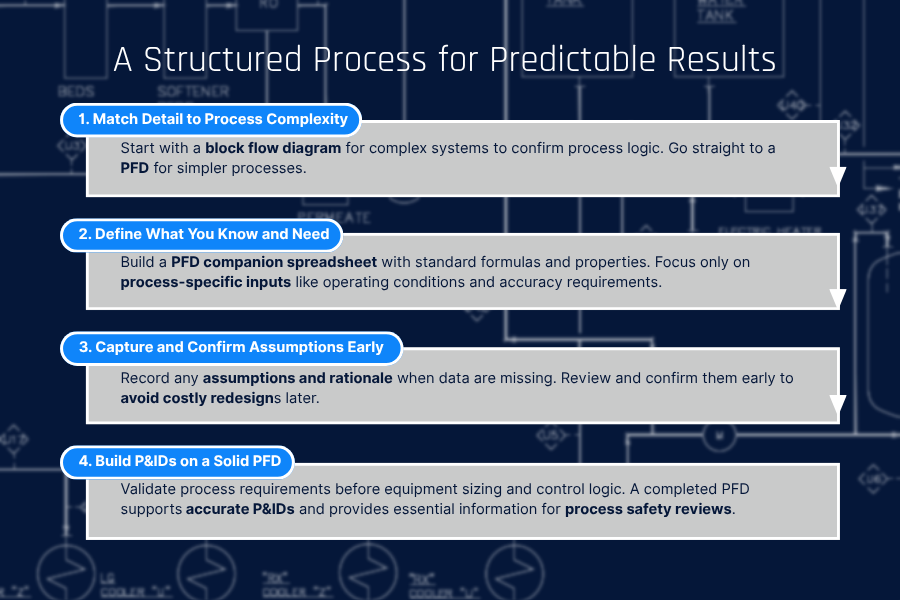

It is imperative to understand at what point the project begins and ends within the process. A block flow diagram is a basic yet effective way of communicating that scope. The simplest of block flow diagrams show basic unit operations, and how the flow of material moves throughout the process. This is necessary for the engineer to get a general idea of what the process consists of, and it is also helpful for the owner to make sure they have all steps of the process accounted for.

The next step is to break out the unit operations within the block flow diagram to generate the process flow diagram. The purpose of the process flow diagram is to give more detailed information as to how each piece of equipment within the system affects the process parameters. In general, the focus should be on material, flow, and fluid property (pressure, temperature, viscosity). It is also wise to include any other pertinent information that the engineer would need to have regarding the flow, such as required accuracy of a particular parameter, or if heat transfer is involved, the applicable energy related properties. In general, the process flow diagram will indicate all equipment and components that change the process flow, and this change will be documented. Some examples of this include:

- Material moving through a pump: change in pressure

- Material condensed in a heat exchanger: change in phase, change in temperature

- Distillation column: change in composition

All the information recorded will assist the engineer in the next steps of the design: P&ID creation and equipment/component specification. Failure to generate a detailed process flow diagram that is agreeable to the owner will lead to incorrect sizing or specification of equipment and pipelines.

Understanding the Hazards

Each process contains its own unique process conditions and hazards, and these must be identified early in the process to design for them. The material itself is generally a source of immediate hazard that must be addressed. Collection of material information to understand how the material affects the environment around it is important. This can include chemical compatibility that will dictate acceptable materials of construction. Corrosion of piping materials must be limited or accounted for within the design. Additionally, it must be known what elastomers are acceptable to reduce swelling and deterioration which may lead to leaks. Other factors such as flammability or combustibility will affect selection of electrical components based on the required area classification. If these hazard questions are not addressed, the incorrect materials may be ordered for the process. This could lead to requoting/reordering of materials if caught early enough, or could lead to component failure in the field.

Engagement of Other Disciplines

Rarely is a project ever solely process based. A team of disciplines is generally required to complete a project, and it is important to engage with these groups early on. Collaboration with safety and regulatory teams from the outset is essential.

Each customer or customer site may have their own set of safety standards that they abide by. While most may be generally accepted practices, others may be very site specific, and it is important to understand those at the on-set of the process design. An example of this may be fluid service classification, and the correct construction and inspection method for that fluid. This could lead to incorrect specification of equipment, piping, or fabrication methods that would invalidate it for use in the process. Similarly, regulatory constraints should be considered early in process design. Chemical emissions are strictly monitored, and this may require rework in how a vent stream is captured. This may be done with additional equipment, or in the worst case, rework of the process.

Laying the groundwork is pivotal in process engineering. While the topics listed are not exhaustive, they serve as a background as to the types of information to be gathered prior to any equipment and component specification begins. Taking the time to research these items beforehand will lead to less rework, both on the design side and in the field.