What are Piping Isometrics?

When most people think about piping design, they picture the 3D model: smart software, clean routing, maybe even a Navisworks walkthrough. But to the fabrication shop and field crews, the 3D model is just the beginning. What actually gets built is based on the piping isometrics.

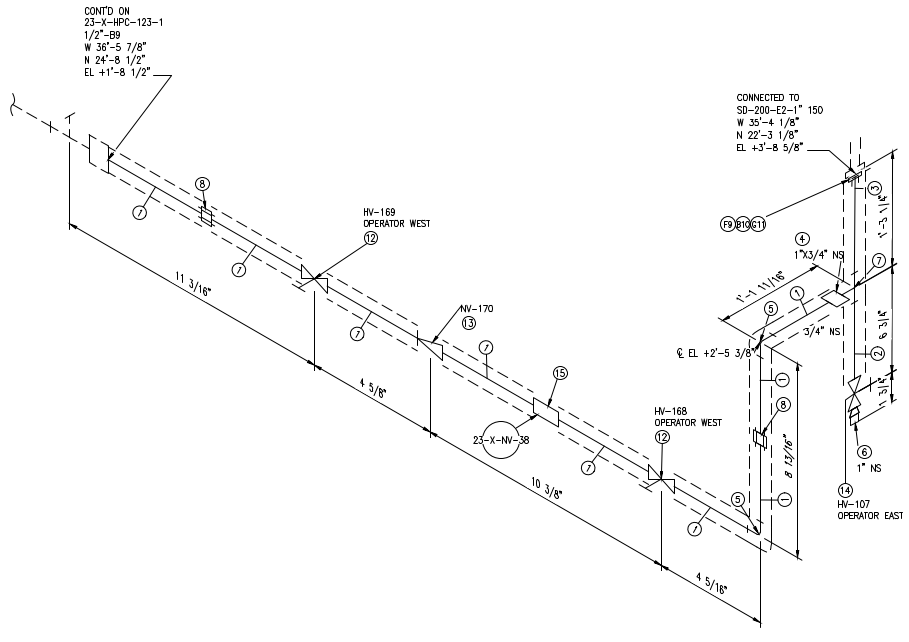

Piping isometrics (or “isos”) are the final, and arguably most important, deliverable in a piping design package. They’re not just drawings. They’re instructions for fabrication and installation. Detailed inspection for QA/QC is critical, as isos are often the last chance to catch errors before pipe hits the shop floor.

Key Elements of High-Quality Piping Isometrics:

- Complete Bill of Materials (BOM): Every component down to nuts, bolts, and gaskets, all compliant with industry, customer, and client specifications

- Precise Dimensions: All component placements and pipe lengths clearly defined

- Clear Tag Numbers: Equipment, instrument, and valve identifiers matching the P&ID and instrument list

- Tie-In Callouts: Specific connection points to existing systems with clear descriptions

- Installation Notes: Special requirements for wall penetrations, supports, or other construction details

- USC Coordinate Reference: Clearly identified User Coordinate System (USC) origin and orientation so installer can relate isometric dimensions to real-world 3D environment.

- Readable Layout: Avoids clutter and overlap, even if it means splitting across sheets.

Why Piping Isometrics Matter

Cost and Time Efficiency

- Prefabrication Advantage: Accurate isos allow piping to be fabricated in a controlled shop environment rather than on-site. This not only improves quality but dramatically reduces cost and install time.

- A recent project leveraging isometrics enabled a 70% reduction in costly onsite labor and achieved a 38% total installation cost savings compared to field routing without isometrics.

- Competitive Bidding: Because isos include a full bill of materials, they enable competitive bidding on fabrication and install. Contractors know exactly what’s included, so bids are apples-to-apples.

- Reduced Uncertainty: Clear isos reduce uncertainty, so contractors price less risk into their bids. The added transparency typically results in lower bids as contractors don’t need to add contingencies for unclear scope.

- Reduced Change Orders: When piping isometrics accurately reflect field conditions and design requirements, expensive field changes become far less common.

- Reduced Field Labor: Shop fabrication eliminates travel, access, hot work, and scheduling constraints that slow field work.

Common Mistakes in Piping Isometrics

Even small errors in an isometric can ripple into costly delays. Some of the most frequent issues we see include:

- Incomplete Bills of Materials: Generic placeholder items or missing components

- Missing or Incorrect Tag Numbers: Mismatches between piping isometrics, P&IDs, and instrument lists

- Cluttered, Unreadable Layouts: Overlapping dimensions and text that make interpretation difficult

- Missing Reference Points: No clear indication of where measurements originate

- Poor Revision History: Unclear documentation of what changed between versions

- Inconsistent Specifications: Materials or components that don’t align with project requirements

How C-P Systems Approaches Piping Isometrics

We don’t treat isos as a formality or just another output from the model. They’re a critical step in ensuring that the piping system can be safely fabricated, installed, and supported in the field without surprises.

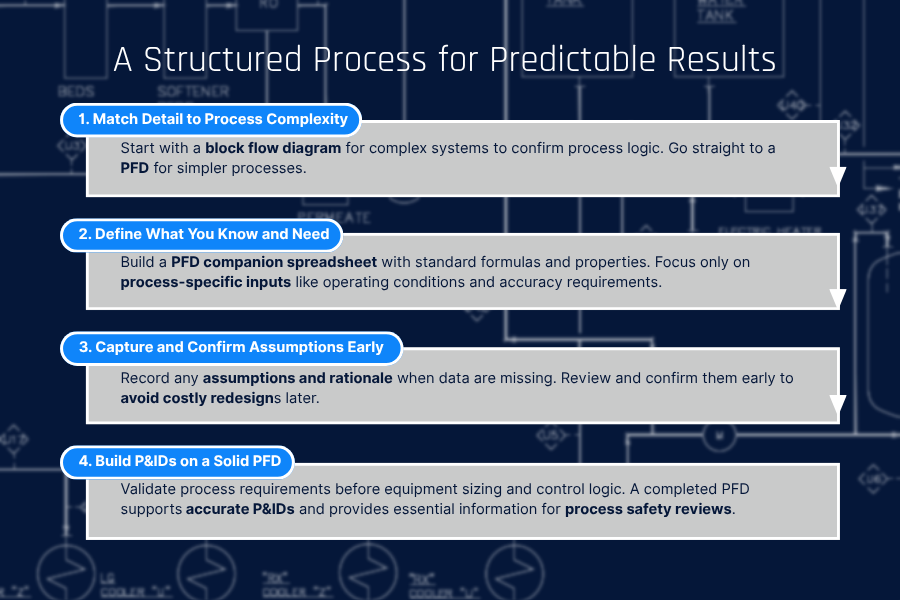

- Build Foundation We begin with meticulous information gathering:

- Accurate Laser Scans: Complete scans capture the entire installation area including tie points to ensure field accuracy

- Comprehensive PFDs and P&IDs: Fully developed process diagrams (PFDs) and Piping and Instrument Diagrams (P&IDs) serve as the foundation for the 3D model

- Detailed Specifications: Thoughtful and clear selection of piping specifications to match each specific service in scope

- Spec-Driven Design Process Our 3D modeling software includes built-in specifications:

- Client specifications are built into our 3D modeling software to ensure alignment between our isometrics and client standards.

- For clients who don’t have their own piping specifications, we will build them and ensure alignment with process requirements.

- Our model enforces specification rules throughout, eliminating non-compliant components by design

- BOMs are populated automatically from verified and in-spec materials

- Rigorous Quality Assurance We implement thorough verification of each isometric:

- Cross-checking between P&IDs, instrument lists, valve schedules, and equipment data

- Verification that all components meet mechanical integrity requirements for pressure, temperature, and corrosion resistance

- Review by key stakeholders including maintenance, operations, and engineering to confirm system operability in the long run

We recognize that even the best isometric can’t show everything. Surrounding obstructions, demolition scope, and real-world field conditions fall outside of what a piping isometric can effectively convey. That’s why we supplement most piping design packages with annotated laser scan imagery to more clearly note existing conditions, new piping overlays, exact tie-point locations, and any associated demolition work. These visuals aren’t part of the iso itself, but they add critical context to help prevent costly field errors, especially when working in tight areas and where demolition is involved.

Key Takeaway: Piping Isometrics Are an Investment, Not a Cost

The most important thing to remember about piping isometrics is that they aren’t just technical documentation. They represent the critical transition point where design becomes reality. A well-prepared isometric drawing package delivers:

- Reduced installation time and cost through prefabrication

- Fewer RFIs and installation errors

- Lower total project costs through accurate bidding

- Systems that operate as designed from day one

The better the iso, the fewer the questions, and the smoother the install.