At C-P Systems, we encounter these issues daily and have honed our processes to effectively address them. Let’s explore the key challenges shaping today’s construction documentation landscape.

The Challenges

1. The “Hand Waving” Mentality

In construction, “hand waving” refers to casually dismissing design and planning concerns, thinking instead that you can design-as-you-build. The phrase comes from engineers and foremen standing in the field and waving their hands where the piping and equipment should be installed . In the past, experienced engineers ensured that design decisions were validated before construction. With the loss of this institutional knowledge, hand waving has become a fallback approach. While this approach might work in tightly knit teams with well-established trust, understanding, and extremely perfectly aligned expectations, it often backfires in more complex or fragmented project environments.

The negative result of this mentality is lack of big-picture context, thorough review from stakeholders, diminished value of design, and a less constructible, operable, and maintainable design.

Without thoroughly documented construction packages, bidders face uncertainty, leading to higher costs, misaligned expectations, and diminished project quality. The “hand wave” approach is not just a construction problem—it’s a design and project management issue that can derail an entire project.

2. Over-Reliance on Technology Without Context

Technology has transformed how we design and document projects, yet it has also created significant gaps in understanding. As the saying goes, many users now “understand the calculator, but not the math.”

As an example, tools like SolidWorks and Revit are excellent for visualization; however, they are often misapplied to piping design. These programs lack the functionality to utilize piping specifications, output a piping isometric construction drawing, produce a bill of materials, or account for operational realities like accessibility, maintenance, or safety.

The result? Designs that look impressive, but fail in practicality. Without the right expertise to bridge the gap between software capabilities and engineering fundamentals, projects can suffer from inefficiencies, unexpected modifications, and costly delays.

3. The Push for Cheaper, Faster, and Less Detailed

The demand for faster timelines and reduced costs has introduced a dangerous trade-off: speed at the expense of quality.

Too often, projects are driven by unrealistic expectations—where the goal is to reduce budgets and shorten schedules without considering the expertise required to execute successfully. This approach frequently leads to higher costs, more rework, and longer delays that ripple throughout the project.

The real cost of prioritizing speed over quality is:

- Incomplete or inaccurate designs that cause issues downstream

- Hidden costs from change orders and rushed decision-making

- Increased project risks due to overlooked safety or operational concerns

The right expert can solve these issues upfront, saving both time and money. But all too often, the pursuit of “cheaper and faster” results in the opposite: slower, costlier outcomes.

4. Siloed Processes and the Shift in Generational Workforce

Specialization in design and engineering is essential, but it has created a more siloed workflow across disciplines, companies, and within teams. This lack of integration often leads to blind spots in project goals, timelines, and the critical path, which hinders efficient project execution.

Compounding this issue is the ongoing generational shift in the workforce. This shift has created a gap in practical knowledge, particularly in areas where engineering intuition is required to question flaw and gaps in the constructability of designs.

Without cross-discipline collaboration and knowledge continuity, project suffer from incomplete documentation, overlooked operational realities, and increasing reliance on less experienced personnel who may lack insight to recognize fundamental design flaws before they become costly issues.

5. The Undervaluing of the Final Mile

The final phase of any project—the last 10%—is where true value is delivered. This is the stage where designs are refined for constructability, operability, and maintainability. Yet it’s often rushed or overlooked entirely, leading to incomplete packages that fail to meet operational needs.

When the final mile of a project is overlooked, small design errors escalate into costly construction problems; unclear documentation leads to RFIs and unnecessary rework; and insufficient refinements result in long-term maintenance challenges and operational risks—all ultimately leading to project delays. Rushing or skipping this critical step doesn’t save time; it creates delays as teams scramble to address overlooked issues during construction.

Our Approach: Tackling These Challenges Head-On

At C-P Systems, we’ve developed a structured, disciplined approach to overcome these challenges, ensuring every construction package we deliver is precise, practical, and ready for execution.

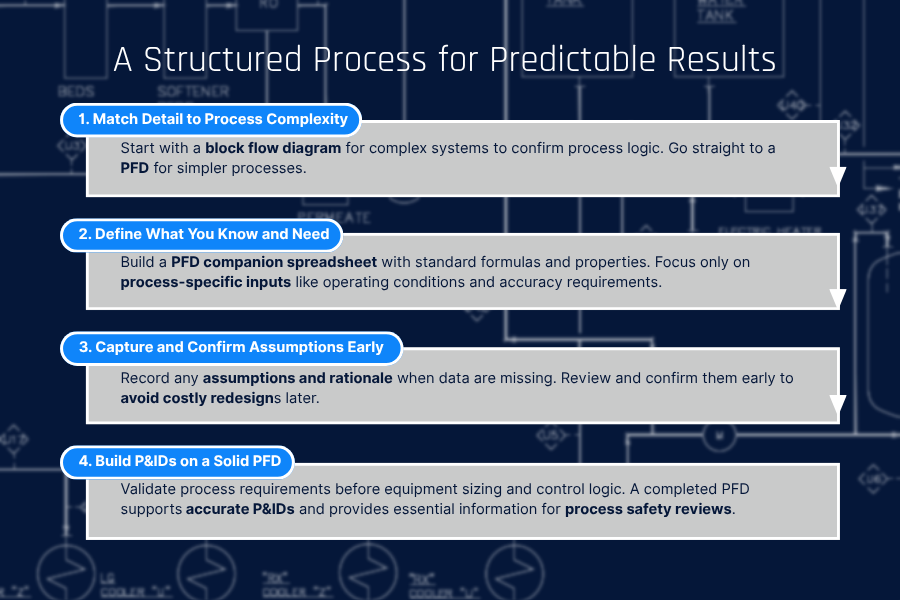

A Proven, Step-by-Step Process

We believe in the old military adage, “slow is smooth, smooth is fast.” By following a time-tested, well-documented process, we ensure that every phase of the project builds on a solid foundation. This reduces the need for rework and keeps projects on track.

Balancing Technology with Expertise

While we leverage advanced tools, we never lose sight of the importance of hands-on experience. Our team understands not just the software, but also the real-world applications of design, ensuring every deliverable is operationally sound and maintenance-friendly.

Deliverables that Minimize Ambiguity

We produce construction packages that limit guesswork and provide clear, actionable, and consistent documentation. The complete mechanical construction packages include all the documentation needed to bid and construct the system. Among other things, they include P&IDs, piping isometrics, and equipment layout drawings. As a whole, the package is designed to level the playing field for bidders, reduce uncertainty, and maximize cost savings.

Acknowledging Our Strengths—and Our Limitations

Unlike “one-stop shops” that often overpromise and underdeliver, we’re transparent about our capabilities. When a project requires expertise beyond our core strengths, we collaborate with trusted partners to deploy the right resources for the job.

The Final Mile Done Right

We dedicate the time and resources needed to refine every detail during the final phase of a project. This ensures that our construction packages are not only complete, but also aligned with operational, safety, and maintenance goals.

Designing with Intent—Not Hand Waving

Every project we take on includes structured reviews at key milestones, ensuring we stay aligned with stakeholder goals. By addressing potential issues early, we avoid the pitfalls of hand waving and deliver packages that are ready for construction.

The Path Forward

The challenges presented by modern construction packages are complex, but with the right experience, they don’t have to be unpredictable. At C-P Systems, we’re committed to delivering clarity, precision, and practicality to every project we undertake.

By embracing a methodical approach, leveraging the right expertise, and prioritizing thoroughness over shortcuts, we ensure that our clients receive the quality and value they deserve.

Reach out to us if you’re ready to experience a better way to approach industrial projects.

Piping Design + Engineering

Benefit from expert material selection, precise piping specifications, routing, and stress analysis, all supported by detailed 3D models for safe, efficient, and maintainable layouts.