C-P Systems

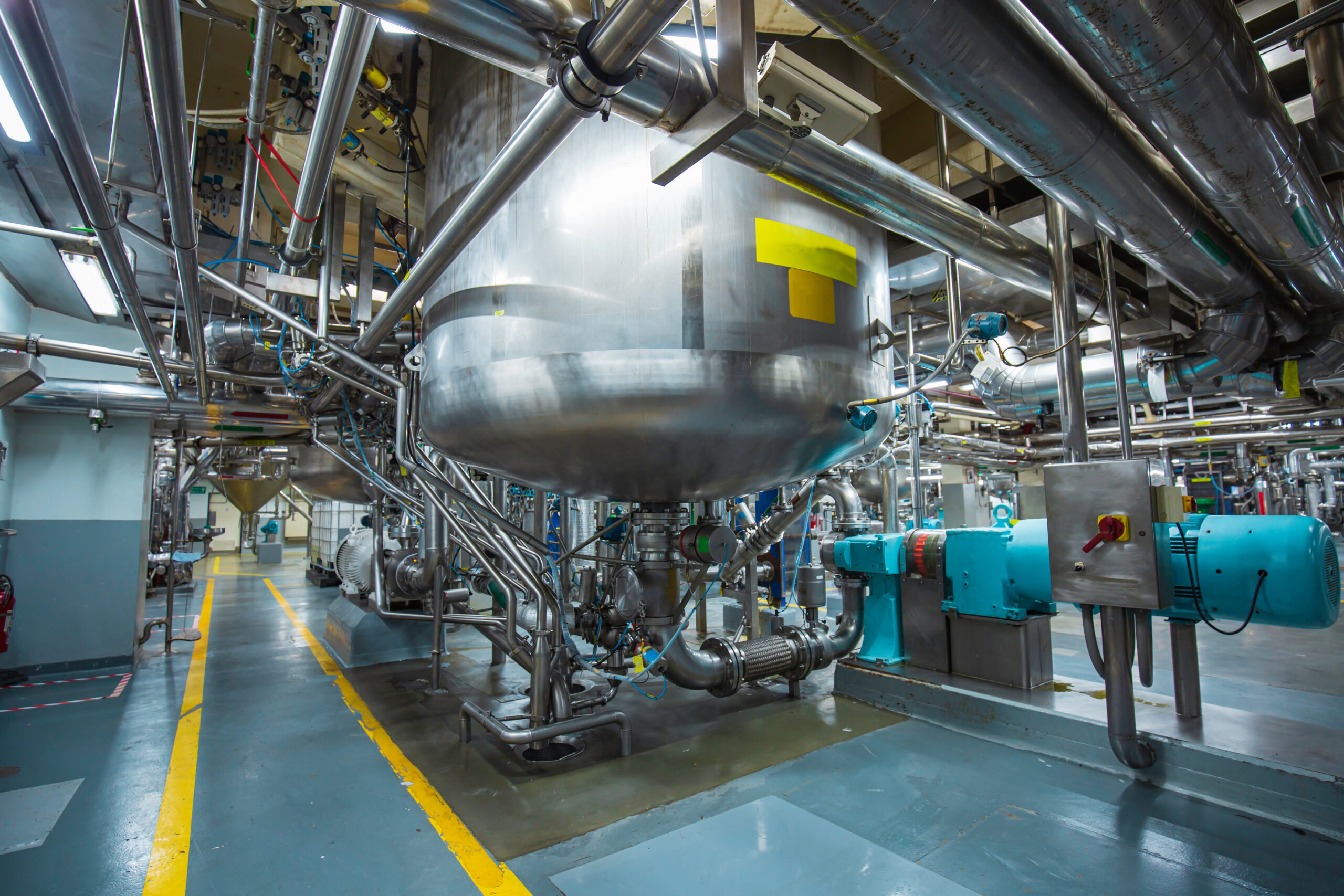

SPECIALTY CHEMICAL

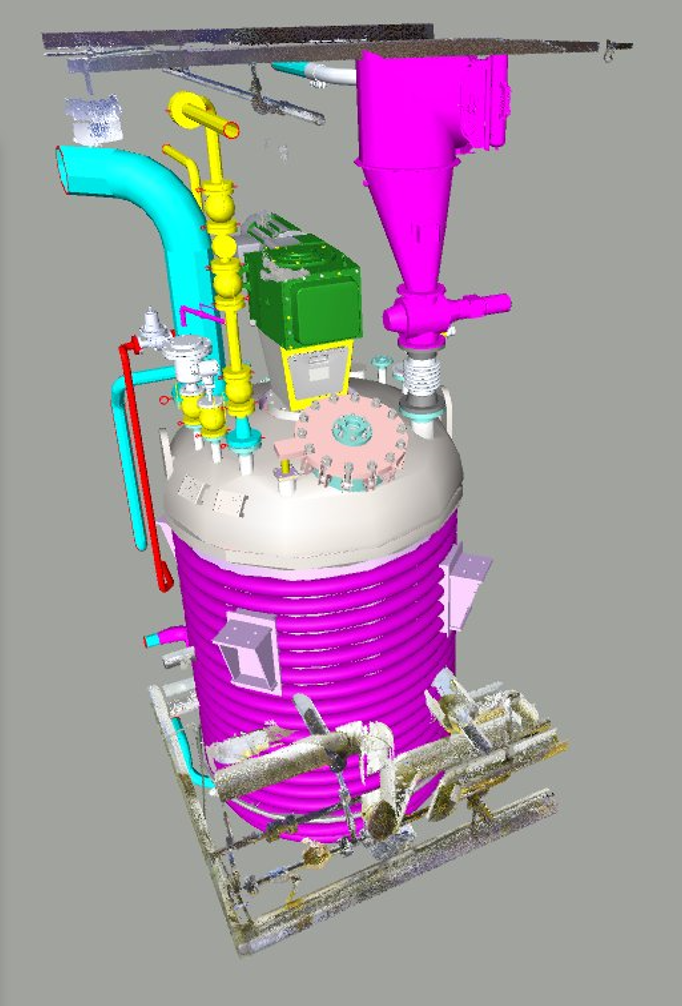

Specialty chemical processes present unique challenges, requiring tailored solutions to ensure safety, efficiency, and compliance with rigorous standards such as OSHA PSM 1910.119, API 520/521, and ASME codes. You need a partner who understands the complexities of reactive systems, material compatibility, non-Newtonian fluid dynamics, and high-pressure or thermal hazards—and who can design systems that keep operations running smoothly. C-P Systems brings decades of experience and innovation to optimize your production, minimize downtime, and provide actionable designs that meet the stringent demands of specialty chemical applications.

Key Applications

HAZARDOUS MATERIAL HANDLING

COMPLEX UNIT OPERATIONS

RELIEF SYSTEM DESIGN

HEAT EXCHANGER SYSTEMS

BULK STORAGE + TRANSFER SYSTEMS

PROCESS OPTIMIZATION

INTERCONNECTED SYSTEMS

Backed by Industry Experience

3

DECADES OF EXPERIENCE IN SPECIALTY CHEMICAL

3500+

INSTALLATIONS MANAGED

$1B

TOTAL CAPITAL INVESTMENTS MADE

Key Services

We combine comprehensive services—including piping design, relief system studies, and process engineering—with essential deliverables, such as Piping and Instrumentation Diagrams (P&IDs), Process Flow Diagrams (PFDs), and equipment specifications, to develop a detailed mechanical construction package that ensures clarity, safety, and reliability at every stage, from concept to implementation.

Safety Through Thorough Understanding

In specialty chemical processing, safety and compliance are critical to every phase of your operations. C-P Systems delivers end-to-end safety solutions, from designing compliant relief systems to conducting process hazard analyses and developing detailed safety documentation. Our designs prioritize protecting personnel, equipment, and the surrounding community through documentation, industry expertise, compliance reviews, and best practices. By addressing the risks of hazardous materials and complex systems, we help you meet OSHA PSM 1910.119, API 520/521, and ASME standards—ensuring safe, reliable, and efficient operations at every step.

Meet the Experts

Jeff Carusa

Jeff brings over 15 years of experience in chemical engineering, with a focus on equipment design, fabrication, and installation. As a licensed Professional Engineer, Jeff excels in managing complex projects from concept to implementation, with deep expertise in Process Safety Management (PSM), mechanical integrity, and maintenance reliability. His hands-on leadership in developing reliability programs and optimizing asset uptime highlights his commitment to operational efficiency and safety. Jeff’s innovative approach and proven ability to deliver value-driven solutions make him an invaluable asset to any project.

Resources

BLOG

The Cost Savings of Reducing Uncertainty through Front-End Engineering & Design (FEED)

Learn how upfront planning through Front-End Engineering and Design (FEED) studies can significantly reduce project uncertainty and control costs. Explore how a small investment in a FEED study can lead to substantial savings by minimizing risk premiums, contractor markups, and cost overruns. Discover how strategic planning can safeguard your project and ensure a smoother execution.

BLOG

Initial Considerations for Designing a New Pressure Vessel

Understand the key factors for designing a new pressure vessel, including pressure and temperature ratings, material selection, and configuration. Learn how thoughtful design decisions minimize costs, ensure safety, and optimize performance for your specific application. Explore how detailed upfront planning can set your project up for success.

C-P Systems

CONTACT US

Contact us today to discuss feasibility study options for your project.