C-P Systems

FEASIBILITY STUDIES

When you’re planning a complex manufacturing project, you need confidence that your investment will pay off and your project can be executed smoothly. Feasibility studies address key concerns, such as technical feasibility with up-front engineering, overall compatibility with a detailed review of instrumentation and equipment, and whether a process will fit into your existing infrastructure with laser scanning.

Whether you’re assessing new processes, reviewing equipment options, or evaluating project scope, a feasibility study ensures you have the right information to make informed decisions and move forward with confidence.

Feasibility Study Services

FEED Studies

Material and Energy Balances

Novel Process Studies

Pressure Vessel Calculations

Design Feasibility

Utility Studies

What a Feasibility Study with Us Looks Like

Our feasibility studies are not one-size-fits-all. We customize each study to align with your specific project goals, budget constraints, and timeline. This flexibility ensures that we focus on the most efficient critical path to reach the conclusion critical to moving on to the next phase of your project. Whether you’re looking to further develop your project scope to an actionable level of detail or looking for a robust FEED study with detailed engineering and implementation resources, our goal is to help you set your project up for success.

Deliverables can include:

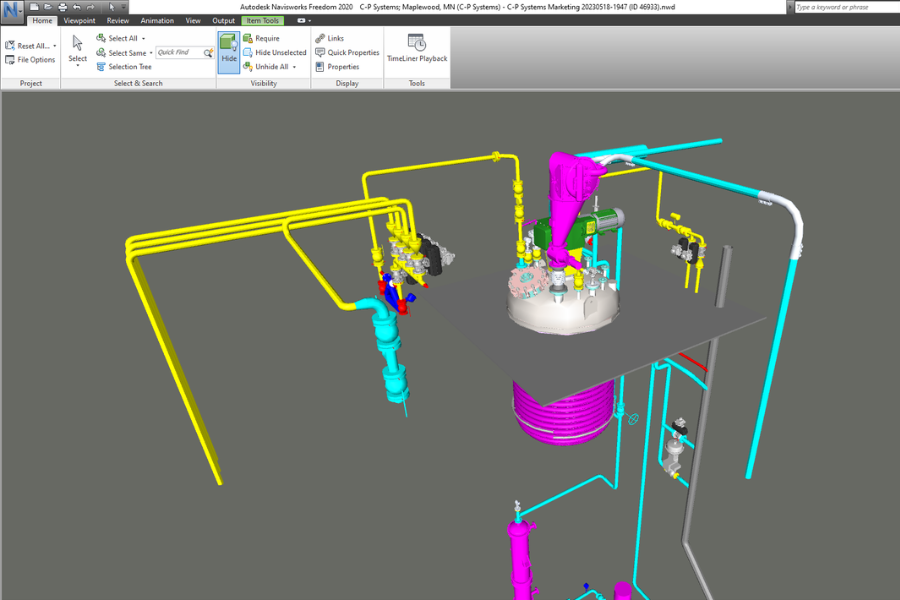

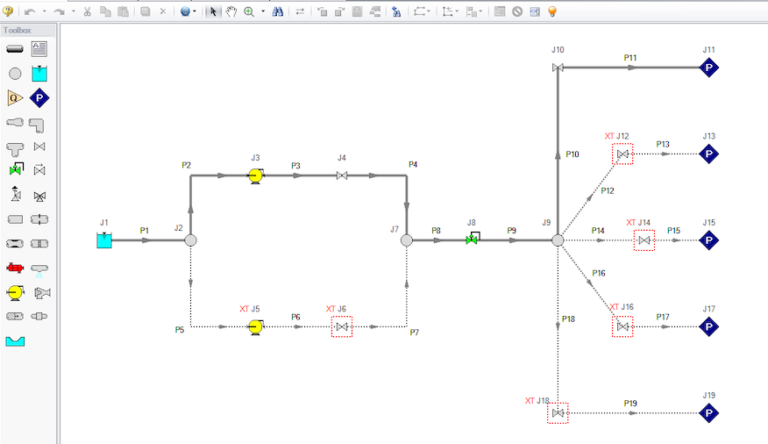

- Detailed process flow diagrams (PFDs) with material and energy balance

- Piping and instrumentation diagrams (P&IDs)

- 3D models and visualizations

- Comprehensive cost estimates (to customer-specified tolerances)

- Project schedules and timelines including critical path milestones

- Risk assessment and mitigation plans

- Presentation of process alternatives

Backed by Industry Experience

C-P SYSTEMS

30

YEARS OF C-P SYSTEMS

400+

YEARS OF COMBINED EXPERIENCE

3500

INSTALLATIONS MANAGED

$1B

CAPITAL INVESTMENTS

Meet the Experts

Michael Swift

Mike brings more than 20 years of engineering and design experience across industries and with it a wealth of knowledge and expertise to each feasibility study. He has successfully led projects in specialty chemicals, food and beverage, pharmaceuticals, renewable fuels, and consumer products. Known for his keen attention to detail and strong focus on safety and process design, Mike will ensure your satisfaction from concept to startup.

About C-P Systems

Why C-P Systems

We bring unparalleled expertise to every feasibility study we perform, with a strong emphasis on detail and precision. Deep industry knowledge, combined with advanced technologies like laser scanning and 3D modeling, allows us to accurately and reliably assess project viability.

We are committed to delivering high-quality, cost-effective solutions that provide great economic value to our clients. Our experience and attention to detail enable us to optimize project scopes, streamline project timelines, and ensure that your project is completed safely, efficiently, and on budget. We provide comprehensive data to help you make informed decisions.

Resources

The Cost Savings of Reducing Uncertainty through Front-End Engineering & Design (FEED)

Learn how upfront planning through Front-End Engineering and Design (FEED) studies can significantly reduce project uncertainty and control costs. Explore how a small investment in a FEED study can lead to substantial savings by minimizing risk premiums, contractor markups, and cost overruns. Discover how strategic planning can safeguard your project and ensure a smoother execution.

C-P Systems

CONTACT US

Contact us today to discuss feasibility study options for your project.