C-P Systems

PROCESS ENGINEERING

You know your production processes better than anyone, but when it comes to ensuring they are efficient, safe, and scalable, you need a partner who can guide the critical details. You need someone who will align every design decision with your goals while addressing infrastructural, operational, and design constraints. Whether it’s optimizing your systems for compliance or long-term reliability, C-P Systems applies a focused, methodical approach grounded in decades of industry experience. We focus on the critical path to ensure momentum is maintained, providing quick solutions and alternatives to keep your project on track. From concept to completion design, we streamline your processes without sacrificing thoroughness or precision.

Process Engineering Services

Custom Process Development

Process Repurposing

Process Additions

Process Reviews

Safety and Risk Management

Benefits of Process Engineering

EXPEDITE CONSTRUCTION TIMELINES

REDUCE PROJECT COST

DECREASE DOWNTIME

MINIMIZE CHANGE ORDERS

Our Proven Approach

Our approach to process engineering is honed for precision and efficiency. We streamline every phase, from initial scoping to final construction, allowing you to stay focused on your operations while we handle the logistics. Our step-by-step process involves gated reviews and close collaboration with your team to ensure transparency and quality throughout the project. With detailed planning we handle the technical complexities to take your project flawlessly from the drawing board to the job site.

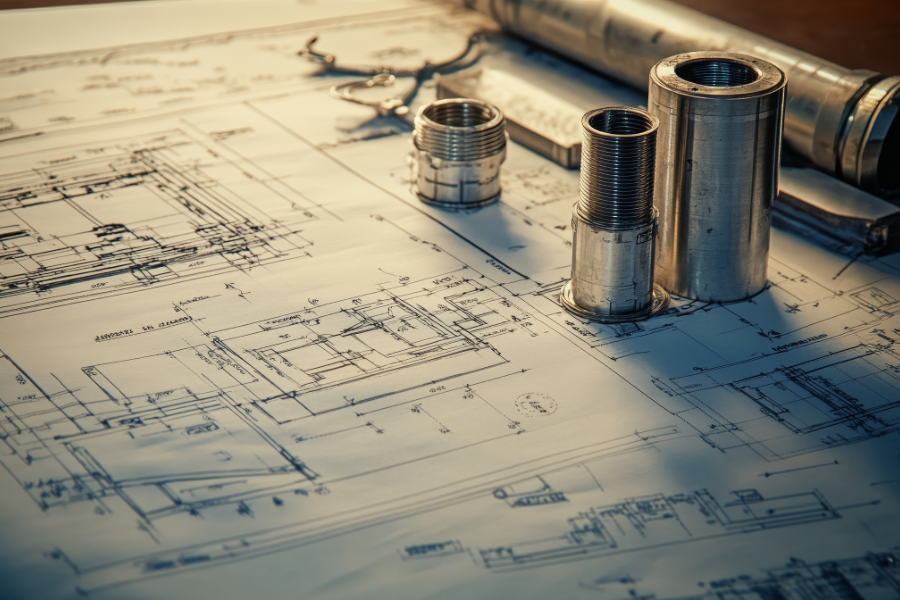

Detailed Process Mechanical Construction Packages

Our deliverable packages provide everything you need to go from concept to construction, with detailed engineering diagrams, models, and specifications. These comprehensive packages ensure a seamless transition to installation and construction, covering all aspects of process and mechanical systems.

Deliverables can include:

- Mechanical Construction Package

- Piping and Instrument Diagrams (P&ID)

- Equipment, Instrument, and Valve Sizing and Specifications

- Process Flow Diagrams (PFD)

- 3D Process Modeling

- Material and Energy Balances

- Safety Analyses

- Relief System Documentation

Meet the Experts

Jeff Ormsbee

Jeff brings a passion for creating innovative solutions to complex process engineering and design opportunities. With nearly 15 years of experience across industries, he adeptly applies project management skills to chemical engineering challenges. Jeff’s strong background in problem solving, data analysis, communication, and organization will ensure efficiency for your processes.

About C-P Systems

Why C-P Systems

More than expertise, it’s flexibility and precision that set us apart. At C-P Systems, we have honed our approach through three decades of extensive experience to deliver quick, tailored solutions across a variety of industries and process requirements. We don’t stop at a one-size-fits-all approach; we take the time to align our services to your specific budget, safety, and operational needs, ensuring compliant and efficient results even in the most hazardous and complex environments.

Process Engineering Services

Feasibility Studies

Receive a thorough assessment of technical feasibility, process compatibility, and seamless integration with your existing infrastructure or a detailed front-end engineering and design (FEED) study.

Relief Studies

Ensure safe and compliant pressure release of your process equipment with comprehensive evaluation and design of relief systems.

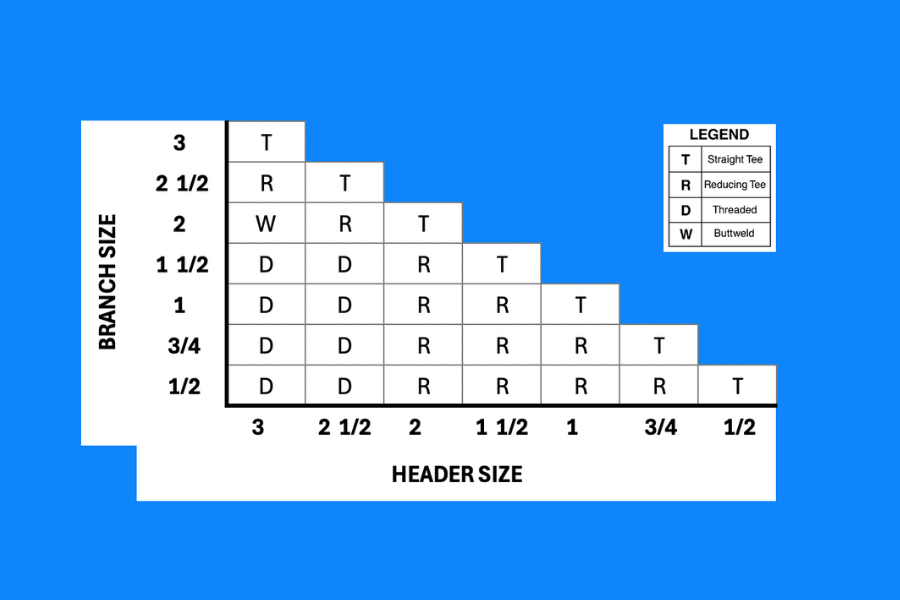

Piping Design + Engineering

Benefit from expert material selection, precise piping specifications, routing, and stress analysis, all supported by detailed 3D models for safe, efficient, and maintainable layouts.

Process Mechanical Consulting

Achieve mechanical safety, reliability, and optimal performance in complex industrial environments by working with specialized experts in unique process fluids, custom equipment, and integration into existing systems.

Process Safety Management

Receive expert support in process safety management, specializing in managing highly hazardous chemicals, enhancing operational integrity, and implementing regulatory safety controls for reliable, compliant industrial processes.

Frequently Asked Questions

What is process engineering?

Process engineering is the discipline of designing and optimizing chemical and physical processes used in industrial production. At C-P Systems, we focus on the practical challenges of scaling industrial processes: heat and mass balances, equipment sizing, safety considerations, and making sure what works in the lab actually works in your plant. Our chemical engineering foundation means we understand both the chemistry and the engineering needed to make processes successful. It overlaps with chemical engineering but extends to system integration, scale-up, control strategies, and operational improvements in industrial plants.

What types of processes do you specialize in?

Our process engineering services support a wide range of processes including mixing, heating, cooling, separation, filtration, material handling, industrial reactions, and more. We apply real-world industry experience and in-depth engineering knowledge to processes across industries including specialty chemicals, consumer products, and food & beverage.

Can you help us scale an existing process?

Yes. We help clients scale R&D processes to operation and production. We go deep into understanding your processes, by identifying risks early and adjusting designs to maintain safety, throughput, and product quality at larger volumes, resulting in designs that best meet your business needs.

Can you support feasibility studies or early-stage planning?

Yes, we can help with planning and feasibility studies. We typically begin with process assessments, mass/energy balances, or preliminary layout planning to help clients validate concepts and make sound go/no-go or budgetary decisions.

What if we don’t have existing process documentation?

Missing documentation is a common challenge we see for many manufacturers, especially with legacy or retrofit systems. If you don’t have existing process documentation, we can replace missing information on your system through site visits, interviews, and equipment walkthroughs, then document it accurately to support upgrades, troubleshooting, or compliance needs. Additionally, laser scanning can provide an accurate baseline for your facility layout.

C-P Systems

CONTACT US

Contact us today to discuss feasibility study options for your project.