C-P Systems

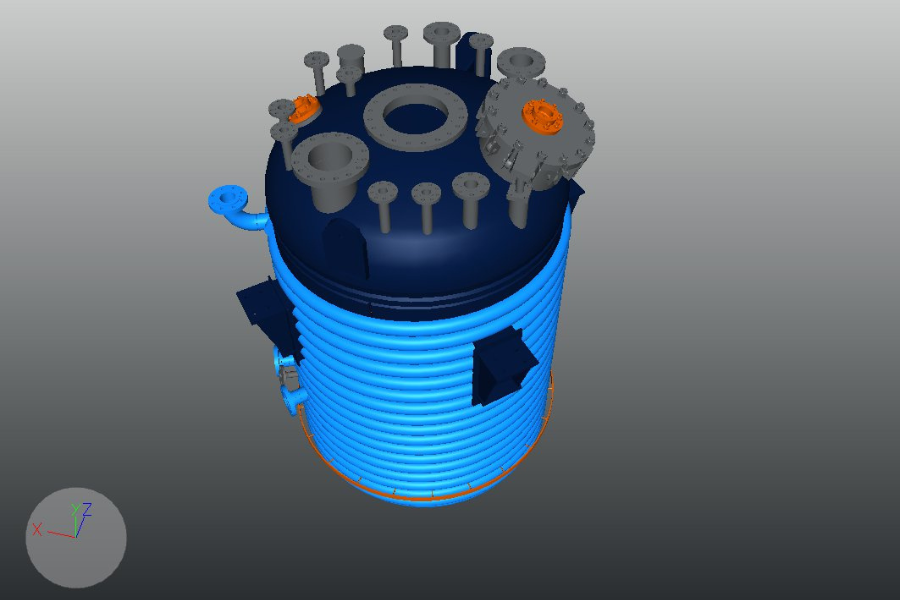

PROCESS EQUIPMENT DESIGN

You need process equipment that integrates seamlessly into your facility—without disrupting operations, creating inefficiencies, or compromising compliance. From scaling production to addressing space constraints to handling complex process conditions like high pressure or corrosive materials, your equipment must be designed for long-term reliability, operability, and safety. Poor layouts, material incompatibilities, and inefficient utility usage can lead to costly downtime and performance issues. With expert process equipment design, you gain solutions tailored to your operational needs, ensuring compliance, efficiency, and maintainability from day one.

Process Equipment Design Services

Equipment Specification and Sizing

Material Selection and Compatibility

3D Equipment Layout and Integration

Utility and Support System Integration

Safety and Regulatory Compliance

Benefits of Process Equipment Design

INCREASED THROUGHPUT

IMPROVED EQUIPMENT LONGEVITY

ACCESSIBLE MAINTENANCE

REDUCED DOWNTIME

About C-P Systems

Smart Designs that Fit Your Goals

At C-P Systems, we design process equipment for real-world performance, ensuring seamless integration, long-term reliability, and compliance. Every system must fit within operational constraints while avoiding inefficiencies, bottlenecks, and maintenance challenges. That’s why we take a holistic approach, considering space limitations, material compatibility, and utility demands from the start.

With decades of hands-on industry experience, we provide tailored solutions for highly regulated industries and complex process conditions. Whether integrating new equipment or optimizing existing systems, our designs deliver reliable performance while enhancing efficiency, reducing costs, and keeping your facility running smoothly.

Clear, Practical Documentation

Our deliverables provide thorough, actionable documentation, ensuring your equipment is designed, specified, and integrated with clarity—minimizing risks and streamlining execution:

- Equipment Specifications, Drawings, and Datasheets

- P&IDs and Process Flow Diagrams

- 3D Equipment Layout Models

- Process and Utility Demand Calculations

- Construction Drawings and Detail Packages

Related Services

Process Engineering

Optimize every step of your processes, from concept to implementation, to achieve efficient, safe, and cost-effective production.

Process Safety

Ensure compliance and reduce safety risks with process safety solutions that integrate seamlessly into your operations, from hazard analysis to regulatory alignment.

Laser Scanning + 3D Modeling

Get accurate as-built conditions and detailed 3D models developed with the latest in laser scanning technology, providing clarity and precision for your projects.

Piping Design + Engineering

Benefit from expert material selection, precise piping specifications, routing, and stress analysis, all supported by detailed 3D models for safe, efficient, and maintainable layouts.

C-P Systems

CONTACT US

Contact us today to discuss feasibility study options for your project.